VI Model Calculations

[68.1.2.1] This section returns to eq. (3.2)

and presents numerical solutions.

[68.1.2.2] This is intended as a case study exploring the relationship

between the statistics of local geometries

and bulk dielectric behavior.

[68.1.2.3] The main focus will be on dielectric enhancement.

[68.1.2.4] To solve eq. (3.2) for ![]() ,

one must know the geometric input functions

,

one must know the geometric input functions ![]() ,

, ![]() and local dielectric responses

and local dielectric responses ![]() ,

, ![]() .

[68.1.2.5] Unfortunately, no experimental data are available at present,[27]

and geometric modeling has to be used instead.

.

[68.1.2.5] Unfortunately, no experimental data are available at present,[27]

and geometric modeling has to be used instead.

A Local dielectric response

[68.1.3.1] The hypothesis of local simplicity states that the local geometries are simple and that the effective local dielectric constants are insensitive to geometrical details other than local porosity. [68.1.3.2] The simplest isotropic local geometry is spherical. [68.2.0.1] For conducting local geometries, a water-coated spherical rock grain will serve as the local model. [68.2.0.2] For blocking geometries a rock-coated spherical water pore is employed. [68.2.0.3] In the notation of Sec. IV, this means

| (6.1) | |||

| (6.2) |

[68.2.0.4] In the low-frequency limit, one obtains for the conducting geometry

| (6.3) |

thereby identifying ![]() in eq. (4.8) as

in eq. (4.8) as ![]() .

[68.2.0.5] The real dielectric constant is found as

.

[68.2.0.5] The real dielectric constant is found as

| (6.4) |

[68.2.0.6] For the blocking geometry, the dc limit gives ![]() ,

in agreement with eq. (4.6), and

,

in agreement with eq. (4.6), and

| (6.5) |

for ![]() , identifying

, identifying ![]() in eq. (4.9),

and

in eq. (4.9),

and ![]() , for

, for ![]() .

[68.2.0.7] Note the presence of the thin-plate divergence in the

.

[68.2.0.7] Note the presence of the thin-plate divergence in the ![]() limit.

limit.

B Local porosity distribution

[68.2.1.1] It was mentioned repeatedly that no experimental data for ![]() are available to the author at present.

[68.2.1.2] A qualitative guideline for porous media resulting

from spinodal decomposition might be the shape

of the order-parameter distribution calculated in Ref. [28]

which suggests in particular that

are available to the author at present.

[68.2.1.2] A qualitative guideline for porous media resulting

from spinodal decomposition might be the shape

of the order-parameter distribution calculated in Ref. [28]

which suggests in particular that ![]() can be bimodal.

can be bimodal.

[68.2.2.1] For the subsequent calculations,

a simple mixture of two ![]() distributions has been used.

[68.2.2.2] The analytic expression reads

distributions has been used.

[68.2.2.2] The analytic expression reads

| (6.6) |

where ![]() ,

, ![]() ,

, ![]() and

and ![]() denotes Euler’s

denotes Euler’s ![]() function.

[68.2.2.3] The bulk porosity is then given as

function.

[68.2.2.3] The bulk porosity is then given as

| (6.7) |

[68.2.2.4] For ![]() , the

, the ![]() densities are bell shaped,

and for

densities are bell shaped,

and for ![]() they diverge at the limits.

they diverge at the limits.

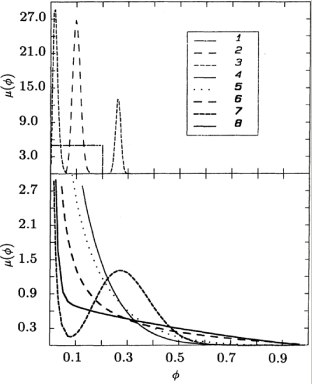

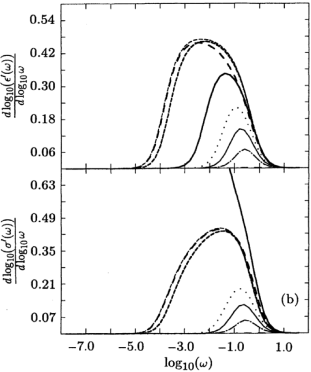

[68.2.3.1] Eight different local porosity distributions

are compared in the calculations.

[68.2.3.2] All of them are chosen such that they give

the same bulk porosity ![]() .

[68.2.3.3] The values of the parameters are listed in Table 1,

and the densities

[page 69, §0]

themselves are displayed graphically in fig. 1.

[69.1.0.1] Each distribution is identified by a number

and a line style as indicated in the inset of Fig. 1.

.

[68.2.3.3] The values of the parameters are listed in Table 1,

and the densities

[page 69, §0]

themselves are displayed graphically in fig. 1.

[69.1.0.1] Each distribution is identified by a number

and a line style as indicated in the inset of Fig. 1.

![]() (

(![]() ) are the partial porosities

) are the partial porosities

![]() in eq. (6.7).

[69.1.0.2] The uniform distribution carries number

in eq. (6.7).

[69.1.0.2] The uniform distribution carries number ![]() and is identified by a thin dot-dashed line.

[69.1.0.3] Number

and is identified by a thin dot-dashed line.

[69.1.0.3] Number ![]() represents the strongly peaked case

and is identified by a wide dashed line,

and so on.

represents the strongly peaked case

and is identified by a wide dashed line,

and so on.

| Curve No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 2/3 | 1 | 1 | 1 | 2/3 | 2/3 | |

| 1.0 | 360.0 | 191.1 | 7.2 | 4.5 | 1.8 | 28.8 | 58.6 | |

| 1.000 | 40.000 | 3.900 | 0.800 | 0.500 | 0.200 | 0.087 | 0.176 | |

| 1423.0 | 13.9 | 2.24 | ||||||

| 500.00 | 6.00 | 0.96 | ||||||

| 0.1 | 0.1 | 0.02 | 0.1 | 0.1 | 0.1 | 0.003 | 0.003 | |

| 0.26 | 0.294 | 0.294 | ||||||

| 0.00333 | 0.00024 | 0.00010 | 0.00010 | 0.01500 | 0.03000 | 0.00010 | 0.00005 | |

| 0.00010 | 0.01000 | 0.05000 | ||||||

| 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Variance | 0.00333 | 0.00024 | 0.01290 | 0.01000 | 0.01500 | 0.03000 | 0.02213 | 0.03541 |

| Skewness | 0 | 0.2657 | 0.6993 | 1.6004 | 1.8679 | 2.3124 | 1.1588 | 2.1176 |

[69.1.1.1] The choices presented in Fig. ![]() are arbitrary.

[69.1.1.2] The reader should bear in mind, however,

that

are arbitrary.

[69.1.1.2] The reader should bear in mind, however,

that ![]() is easily measureable

and cannot be adjusted to fit experimentally

observed dielectric data when comparing

the theory with experiment.

[69.1.1.3] The choices for

is easily measureable

and cannot be adjusted to fit experimentally

observed dielectric data when comparing

the theory with experiment.

[69.1.1.3] The choices for ![]() presented here are intended

as a case study illustrating different possibilities

that might occur in real or artificial experimental systems.

[69.2.0.1] The highly peaked

presented here are intended

as a case study illustrating different possibilities

that might occur in real or artificial experimental systems.

[69.2.0.1] The highly peaked ![]() (curve

(curve ![]() )

represents the limit of weak disorder.

[69.2.0.2] Remember that

)

represents the limit of weak disorder.

[69.2.0.2] Remember that ![]() for ordered systems.

[69.2.0.3] Curve

for ordered systems.

[69.2.0.3] Curve ![]() gives a reference to which other distributions can be compared.

[69.2.0.4] The distributions 4, 5 and 6 have been chosen divergent at

gives a reference to which other distributions can be compared.

[69.2.0.4] The distributions 4, 5 and 6 have been chosen divergent at ![]() with exponents 0.8, 0.5 and 0.2 as examples for distributions

whose inverse first moment does not exist.

[69.2.0.5] Curves 3, 7 and 8 demonstrate the fact that

with exponents 0.8, 0.5 and 0.2 as examples for distributions

whose inverse first moment does not exist.

[69.2.0.5] Curves 3, 7 and 8 demonstrate the fact that ![]() itself might be “of percolation type.”

[69.2.0.6] This occurs if the porous medium contains

two types of porosity or regions

of very different porosities.

[69.2.0.7] For curve 3 the ratio between the two porosities is roughly 100,

and the inverse first moment of

itself might be “of percolation type.”

[69.2.0.6] This occurs if the porous medium contains

two types of porosity or regions

of very different porosities.

[69.2.0.7] For curve 3 the ratio between the two porosities is roughly 100,

and the inverse first moment of ![]() exists.

[69.2.0.8] For curves 7 and 8, the ratio roughly 1000,

and the densities diverge at

exists.

[69.2.0.8] For curves 7 and 8, the ratio roughly 1000,

and the densities diverge at ![]() .

[69.2.0.9] In all cases the distributions were chosen critical

in the sense that the weight

for the higher-porosity component is

.

[69.2.0.9] In all cases the distributions were chosen critical

in the sense that the weight

for the higher-porosity component is ![]() .

.

C Local percolation probability

[69.2.1.1] The local percolation probabilities ![]() can be measured simultaneously

with the local porosity distribution

can be measured simultaneously

with the local porosity distribution ![]() .

[69.2.1.2] However, such a measurement is more difficult

because it requires the approximate reconstruction

of the three-dimensional pore space from

parallel two-dimensional sections.

[69.2.1.3] For this reason geometric modeling of porous media

is most important for this quantity.

.

[69.2.1.2] However, such a measurement is more difficult

because it requires the approximate reconstruction

of the three-dimensional pore space from

parallel two-dimensional sections.

[69.2.1.3] For this reason geometric modeling of porous media

is most important for this quantity.

[69.2.2.1] Three simple models will be compared in the calculations: the uniformly connected model (UCM), the central pore model (CPM), and the grain consolidation model (GCM).

1 Uniformly connected models

[69.2.3.1] In these models ![]() equals a constant, i.e.,

equals a constant, i.e.,

| (6.8) |

[69.2.3.2] In the simplest case, the fully connected model, ![]() .

[69.2.3.3] This means that all local geometries are assumed to be

[page 70, §0]

conducting.

[70.1.0.1] In addition, the case

.

[69.2.3.3] This means that all local geometries are assumed to be

[page 70, §0]

conducting.

[70.1.0.1] In addition, the case ![]() will also be investigated.

will also be investigated.

2 Central pore model

[70.1.1.1] Consider a cubic cell of volume 1 filled with rock.

[70.1.1.2] Inside the cubic cell a centered cubic pore

of side length ![]() (

(![]() ) is cut out.

[70.1.1.3] Now a random process is used to drill cylindrical pores

with square cross section from the faces of the cube toward the central pore.

[70.1.1.4] Sometimes these pores will connect to the central pore,

and sometimes not.

[70.1.1.5] The random process starts with the choice

of an arbitrary face of the cube.

[70.1.1.6] Now choose a random number

) is cut out.

[70.1.1.3] Now a random process is used to drill cylindrical pores

with square cross section from the faces of the cube toward the central pore.

[70.1.1.4] Sometimes these pores will connect to the central pore,

and sometimes not.

[70.1.1.5] The random process starts with the choice

of an arbitrary face of the cube.

[70.1.1.6] Now choose a random number ![]() between

between ![]() and

and ![]() .

[70.1.1.7] If

.

[70.1.1.7] If ![]() , a pore with square cross section

of side length

, a pore with square cross section

of side length ![]() (

(![]() ) is drilled

from the center of the face all the way to the central pore.

[70.1.1.8] The central pore had volume

) is drilled

from the center of the face all the way to the central pore.

[70.1.1.8] The central pore had volume ![]() ,

and the connection pore has the volume

,

and the connection pore has the volume ![]() .

[70.1.1.9] If the random number fulfills

.

[70.1.1.9] If the random number fulfills ![]() ,

then the face is not pierced,

but instead the same volume

,

then the face is not pierced,

but instead the same volume ![]() is removed from the wall in such a way

that the resulting pore space remains disconnected

from the pore space connected to the central pore.

[70.1.1.10] This process is repeated for all six faces of the cube.

[70.1.1.11] The cubic symmetry is not essential,

and a model with different symmetry can be defined similarly.

is removed from the wall in such a way

that the resulting pore space remains disconnected

from the pore space connected to the central pore.

[70.1.1.10] This process is repeated for all six faces of the cube.

[70.1.1.11] The cubic symmetry is not essential,

and a model with different symmetry can be defined similarly.

[70.1.2.1] The result of the process described above

is a cubic cell whose porosity can be expressed

in terms of the side length ![]() of the central pore

and the ratio

of the central pore

and the ratio ![]() as

as

| (6.9) |

[70.1.2.2] According to the definitions in Section II,

the cell is called percolating

if there exist at least one path

within the pore space connecting a face to a face

different than itself.

[70.1.2.3] To obtain ![]() the probability

that either no or exactly one face

is pierced has to be calculated.

[70.1.2.4] This probability euqals

the probability

that either no or exactly one face

is pierced has to be calculated.

[70.1.2.4] This probability euqals ![]() .

[70.1.2.5] Clearly,

.

[70.1.2.5] Clearly,

| (6.10) |

[70.1.2.6] Thus, in the central pore model,

| (6.11) |

where ![]() is that root of eq. (6.9),

which fulfills

is that root of eq. (6.9),

which fulfills ![]() for all

for all ![]() and

and ![]() .

[70.1.2.7] For

.

[70.1.2.7] For ![]() , i.e.,

, i.e., ![]() , it follows that

, it follows that ![]() and thus

and thus ![]() ,

resulting in

,

resulting in ![]() for small

for small ![]() .

[70.1.2.8] On the other hand, for

.

[70.1.2.8] On the other hand, for ![]() one finds

one finds ![]() for

for ![]() and thus

and thus ![]() for

for ![]() .

[70.1.2.9] Thus the general conclusion for the central pore model is that

.

[70.1.2.9] Thus the general conclusion for the central pore model is that

| (6.12) |

where ![]() can range between

can range between ![]() and

and ![]() .

.

3 Grain consolidation model

[70.1.3.1] The grain consolidation model was proposed as a simple geometrical model for diagenesis.[11][70.1.3.2] Its main observation is the existence and smallness of the percolation threshold in regular and random bead packings when the bead radii are increased. [70.1.3.3] In fact, the model has recently been modified such that the critical porosity at which conduction ceases can be arbitrarily small.[12][70.2.0.1] For regular bead packings, this implies

| (6.13) |

[70.2.0.2] For random packings ![]() will be smoothed out around

will be smoothed out around ![]() .

[70.2.0.3] For simplicity, in this paper eq. (6.13)

will be used with

.

[70.2.0.3] For simplicity, in this paper eq. (6.13)

will be used with

![]() .

.

[70.2.1.1] The most important aspect of ![]() is that it determines the control parameter

is that it determines the control parameter ![]() .

[70.2.1.2] According to eq. (6.12),

its behavior near

.

[70.2.1.2] According to eq. (6.12),

its behavior near ![]() can influence

the exponent

can influence

the exponent ![]() in (5.10c).

[70.2.1.3] Note that for the grain consolidation model

the form of

in (5.10c).

[70.2.1.3] Note that for the grain consolidation model

the form of ![]() always implies

that condition (5.10a) is fulfilled,

and universal behavior is expected.

[70.2.1.4] The half-connected model in the uniformly

connected model class is included

to demonstrate the influence of the thin-plate effect.

[70.2.1.5] The shape of

always implies

that condition (5.10a) is fulfilled,

and universal behavior is expected.

[70.2.1.4] The half-connected model in the uniformly

connected model class is included

to demonstrate the influence of the thin-plate effect.

[70.2.1.5] The shape of ![]() in all other cases

gives extremely small probability

to blocking geometries with high porosities.

[70.2.1.6] This is expected to be generally true for interparticle porosity.

[70.2.1.7] This is expected to be generally true

for interparticle porosity.

[70.2.1.8] However, the secondary pore space in real rocks

may contain a significant fraction

of high-porosity blocking geometries.[32]

in all other cases

gives extremely small probability

to blocking geometries with high porosities.

[70.2.1.6] This is expected to be generally true for interparticle porosity.

[70.2.1.7] This is expected to be generally true

for interparticle porosity.

[70.2.1.8] However, the secondary pore space in real rocks

may contain a significant fraction

of high-porosity blocking geometries.[32]

D Numerical results

[70.2.2.1] Numerical solutions to eq. (3.2)

were obtained using an iterative technique.

[70.2.2.2] The iteration was stopped whenever ![]() .

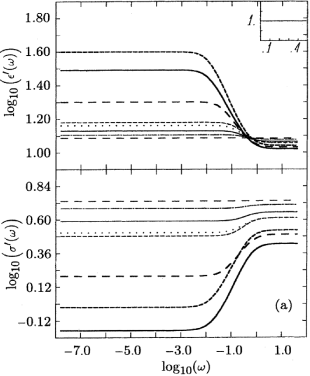

[70.2.2.3] In Figs. 2-5

selected results for

.

[70.2.2.3] In Figs. 2-5

selected results for ![]() are presented.

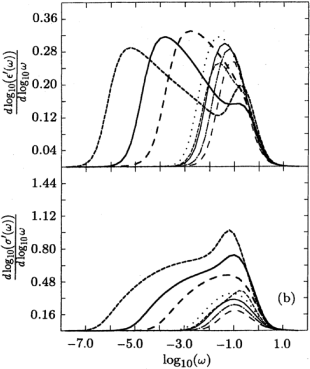

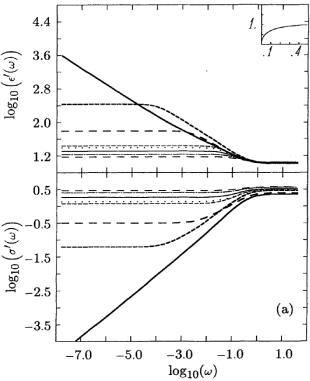

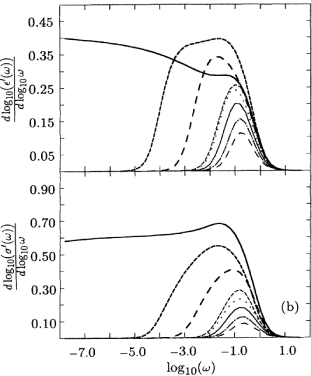

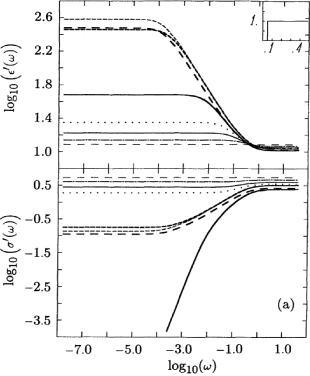

[70.2.2.4] Figure 2 presents the uniformly connected model with

are presented.

[70.2.2.4] Figure 2 presents the uniformly connected model with ![]() ,

Figure 3 the uniformly connected model with

,

Figure 3 the uniformly connected model with ![]() .

[70.2.2.5] Figure 4 gives the results

for the central pore model with

.

[70.2.2.5] Figure 4 gives the results

for the central pore model with

![]() ,

and Fig. 5 those

for the grain consolidation model with

,

and Fig. 5 those

for the grain consolidation model with

![]() .

[70.2.2.6] In each figure the line styles correspond to the line styles

of the local porosity distributions displayed in Figure 1.

[70.2.2.7] Parts (a) of each figure shows

.

[70.2.2.6] In each figure the line styles correspond to the line styles

of the local porosity distributions displayed in Figure 1.

[70.2.2.7] Parts (a) of each figure shows ![]() as a function of

as a function of ![]() in the upper graph and

in the upper graph and ![]() in the lower graph.

[70.2.2.8] In addition, the inset in the upper right-hand corner

displays the local percolation

probability

in the lower graph.

[70.2.2.8] In addition, the inset in the upper right-hand corner

displays the local percolation

probability ![]() for

for ![]() .

[70.2.2.9] The vertical scale for the inset is always

.

[70.2.2.9] The vertical scale for the inset is always ![]() .

[70.2.2.10] Part (b) display in the upper graph

.

[70.2.2.10] Part (b) display in the upper graph ![]() versus

versus ![]() and

and ![]() in the lower plot.

[70.2.2.11] These quantities give a more sensitive

representation of the dispersion

and show at the same time the values

of “local exponents”.

[70.2.2.12] In all figures frequency is measured in units

of the relaxation frequency

of water as discussed in Section IV.

[70.2.2.13] All plots are given over ten frequency

decades with a resolution of five points per decade.

in the lower plot.

[70.2.2.11] These quantities give a more sensitive

representation of the dispersion

and show at the same time the values

of “local exponents”.

[70.2.2.12] In all figures frequency is measured in units

of the relaxation frequency

of water as discussed in Section IV.

[70.2.2.13] All plots are given over ten frequency

decades with a resolution of five points per decade.

|

|

|

|

|

|

|

|

E Discussion

[70.2.3.1] It is obvious from Figs. 2-5 [especially part (b)]

that the low-frequency dielectric response

depends sensitively on the details of ![]() and

and ![]() .

[70.2.3.2] A general discussion is difficult,

because the response is always a mixture

between three basic mechanisms each of which can give

significant dielectric dispersion.

[page 71, §0]

[71.1.0.1] The first mechanism is the dispersion

resulting from the disorder in

.

[70.2.3.2] A general discussion is difficult,

because the response is always a mixture

between three basic mechanisms each of which can give

significant dielectric dispersion.

[page 71, §0]

[71.1.0.1] The first mechanism is the dispersion

resulting from the disorder in ![]() itself.

[71.1.0.2] The second mechanism is the despersion resulting from

itself.

[71.1.0.2] The second mechanism is the despersion resulting from ![]() ,

i.e., from percolation geometry.

[71.1.0.3] The third mechanism is the dispersion

resulting from the behavior of

,

i.e., from percolation geometry.

[71.1.0.3] The third mechanism is the dispersion

resulting from the behavior of ![]() in the

in the ![]() limit, i.e., the thin-plate effect.

limit, i.e., the thin-plate effect.

[71.1.1.1] The absolute dispersion for all figures is collected

in Table 2.

[71.1.1.2] ![]() is defined as

is defined as ![]() ,

while

,

while ![]() .

.

[71.2.1.1] Before discussing the three mechanisms,

it is important to note that the bulk porosity ![]() does not influence the shape of the response curves

if it is changed without changing the shape of

does not influence the shape of the response curves

if it is changed without changing the shape of ![]() .

[71.2.1.2] Instead, it determines an overall frequency shift

for the frequency region over which the dispersion occurs.

[71.2.1.3] As

.

[71.2.1.2] Instead, it determines an overall frequency shift

for the frequency region over which the dispersion occurs.

[71.2.1.3] As ![]() is lowered,

this region is shifted toward lower frequencies.

[71.2.1.4] This observation together with the fact

that all

is lowered,

this region is shifted toward lower frequencies.

[71.2.1.4] This observation together with the fact

that all ![]() give the same bulk

porosity of

give the same bulk

porosity of

![]() shows

that the bulk porosity by itself cannot be used

to characterize the dielectric response.

[71.2.1.5] In particular, there is no theoretical basis

for Archie’s law [eq. (5.27)]

if interpreted as a relation between

dc conductivity and bulk porosity

(see Section V.D for a discussion).

shows

that the bulk porosity by itself cannot be used

to characterize the dielectric response.

[71.2.1.5] In particular, there is no theoretical basis

for Archie’s law [eq. (5.27)]

if interpreted as a relation between

dc conductivity and bulk porosity

(see Section V.D for a discussion).

[page 72, §0]

[page 73, §0]

[73.1.1.1] A second observation is that in all figures

the high-frequency real dielectric constant ![]() is not very sensitive to the details of

is not very sensitive to the details of ![]() .

[73.1.1.2] This is a consequence of the fact

that for low

.

[73.1.1.2] This is a consequence of the fact

that for low ![]() the local dielectric constants

the local dielectric constants ![]() and

and ![]() must both approach

must both approach ![]() .

.

[73.1.2.1] The first mechanism, dispersion from the form of ![]() ,

can be studied in pure form when

,

can be studied in pure form when ![]() ,

and the corresponding results are shown in Figure 2.

[73.1.2.2] In this case there are no blocking local geometries;

i.e.,

,

and the corresponding results are shown in Figure 2.

[73.1.2.2] In this case there are no blocking local geometries;

i.e., ![]() according to eq. (5.7).

[73.1.2.3] If

according to eq. (5.7).

[73.1.2.3] If ![]() is highly peaked as in curve 2,

then the system is only weakly disordered,

and there is almost no visible disperion

with the amount of disorder

contained in

is highly peaked as in curve 2,

then the system is only weakly disordered,

and there is almost no visible disperion

with the amount of disorder

contained in ![]() .

[73.1.2.4] In fact, distributions with power-law

divergences at

.

[73.1.2.4] In fact, distributions with power-law

divergences at ![]() or with percolation structure

generate the strongest dispersion,

as can be seen from curves 3 and 5-8 in figure 2.

[73.1.2.5] Table 2 shows that the dispersion

varies almost three orders of magnitude

between the different distributions.

[73.1.2.6] Note that relatively similar

local porosity distributions

such as curves 6 and 8

can have very different dielectric response.

[73.1.2.7] On the other hand, very different shapes

for

or with percolation structure

generate the strongest dispersion,

as can be seen from curves 3 and 5-8 in figure 2.

[73.1.2.5] Table 2 shows that the dispersion

varies almost three orders of magnitude

between the different distributions.

[73.1.2.6] Note that relatively similar

local porosity distributions

such as curves 6 and 8

can have very different dielectric response.

[73.1.2.7] On the other hand, very different shapes

for ![]() can give similar

can give similar ![]() ,

as demonstrated by curves 3 and 5.

[73.1.2.8] This shows that the dielectric response by itself

does not contain a full geometric characterization

of the pore space,

and it needs always to be complemented

with additional physical or geometrical information.

[73.1.2.9] This is not too surprising.

[73.1.2.10] Indeed, it is more surprising

that when the dielectric response becomes large

it is also very sensitive to geometric details.

[73.1.2.11] This is the case for dielectric enhancement

near the percolation threshold

or as a result of the thin-plate effect.

,

as demonstrated by curves 3 and 5.

[73.1.2.8] This shows that the dielectric response by itself

does not contain a full geometric characterization

of the pore space,

and it needs always to be complemented

with additional physical or geometrical information.

[73.1.2.9] This is not too surprising.

[73.1.2.10] Indeed, it is more surprising

that when the dielectric response becomes large

it is also very sensitive to geometric details.

[73.1.2.11] This is the case for dielectric enhancement

near the percolation threshold

or as a result of the thin-plate effect.

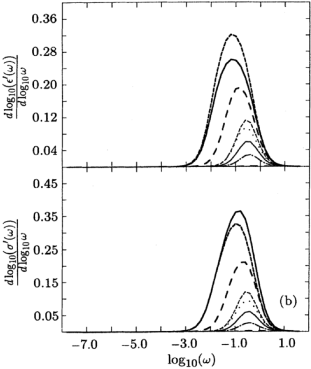

[73.1.3.1] Consider the thin-plate mechanism.

[73.1.3.2] It requires the presence of blocking geometries

of high porosity.

[73.1.3.3] Mathematically, this means ![]() for large

for large ![]() .

[73.1.3.4] As a simple illustration, Figure 3 displays the results

for the uniformly connected model

when

.

[73.1.3.4] As a simple illustration, Figure 3 displays the results

for the uniformly connected model

when ![]() .

[73.1.3.5] Now

.

[73.1.3.5] Now ![]() , which is far away from

, which is far away from ![]() .

[73.1.3.6] Nevertheless, the dielectric dispersion

is much stronger than would be obtained

for solutions to the central pore model

or grain consolidation model with the same

.

[73.1.3.6] Nevertheless, the dielectric dispersion

is much stronger than would be obtained

for solutions to the central pore model

or grain consolidation model with the same ![]() .

[73.1.3.7] Compare, e.g., curve 5 in figure 3

with curve 5 in figure 5.

[73.1.3.8] Moreover, the dielectric dispersion

becomes sensitive to the details

.

[73.1.3.7] Compare, e.g., curve 5 in figure 3

with curve 5 in figure 5.

[73.1.3.8] Moreover, the dielectric dispersion

becomes sensitive to the details ![]() .

[73.1.3.9] It is now possible to distinguish in figure 3(b)

the distributions 3, 7 and 8,

which have

.

[73.1.3.9] It is now possible to distinguish in figure 3(b)

the distributions 3, 7 and 8,

which have ![]() from the rest for which

from the rest for which ![]() .

[73.1.3.10] In particular, curves 3 and 5,

which had very similar response in figure 2,

appear now very different.

[73.1.3.11] The dispersion is the stronger

the more weight

.

[73.1.3.10] In particular, curves 3 and 5,

which had very similar response in figure 2,

appear now very different.

[73.1.3.11] The dispersion is the stronger

the more weight ![]() has at high

has at high ![]() .

[73.1.3.12] This can be seen from curve 3,

which shows less dispersion than curves 4 and 5,

while the opposite was true for figure 2.

[73.2.0.1] Similarly,

.

[73.1.3.12] This can be seen from curve 3,

which shows less dispersion than curves 4 and 5,

while the opposite was true for figure 2.

[73.2.0.1] Similarly, ![]() for curve 7

is depressed below curves 6 and 8 at intermediate frequencies.

[73.2.0.2] At very low frequencies,

the percolative character of distribution 7

is responsible for stronger overall dispersion

than in curve 6.

[73.2.0.3] The degree of asymmetry of

for curve 7

is depressed below curves 6 and 8 at intermediate frequencies.

[73.2.0.2] At very low frequencies,

the percolative character of distribution 7

is responsible for stronger overall dispersion

than in curve 6.

[73.2.0.3] The degree of asymmetry of ![]() is reflected in the asymmetry of the response,

as best seen in the derivatives plotted in figure 3(b).

is reflected in the asymmetry of the response,

as best seen in the derivatives plotted in figure 3(b).

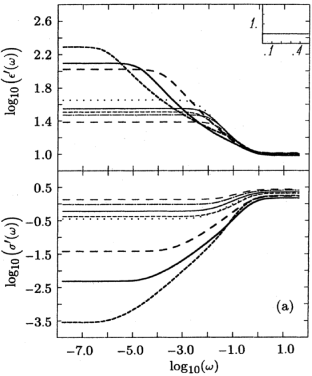

[73.2.1.1] The percolation mechanism is responsible

for strong dielectric disperion

in figures 4 and 5.

[73.2.1.2] There is essentially no dispersion

from thin-plate mechanism in these cases

because in both cases ![]() for

for

![]() ,

and thus there are no local geometrics with

a high dielectric constant.

[73.2.1.3] Figure 4 represents the central

pore model with

,

and thus there are no local geometrics with

a high dielectric constant.

[73.2.1.3] Figure 4 represents the central

pore model with

![]() ,

and results for the grain consolidation model

with

,

and results for the grain consolidation model

with

![]() are given in figure 5.

[73.2.1.4] Contrary to the situation in figures 2 and 3,

are given in figure 5.

[73.2.1.4] Contrary to the situation in figures 2 and 3,

![]() is now different for each distribution.

[73.2.1.5] The results of performing the integral

in eq. (5.7) are listed in table 3.

[73.2.1.6] Naturally, the dielectric dispersion

increases strongly with

is now different for each distribution.

[73.2.1.5] The results of performing the integral

in eq. (5.7) are listed in table 3.

[73.2.1.6] Naturally, the dielectric dispersion

increases strongly with ![]() and this effect dominates the dispersion from

and this effect dominates the dispersion from ![]() itself.

[73.2.1.7] In particular, for

itself.

[73.2.1.7] In particular, for ![]() power-law behavior for

power-law behavior for ![]() as a function of frequency is obtained

in agreement with the scaling theory

presented in Section V.

[73.2.1.8] As an example, scaling theory

predicts the exponent

as a function of frequency is obtained

in agreement with the scaling theory

presented in Section V.

[73.2.1.8] As an example, scaling theory

predicts the exponent

![]() for the conductivity of distribution 8 in figure 4 and

for the conductivity of distribution 8 in figure 4 and

![]() for the real dielectric constants.

[73.2.1.9] These predictions are obtained

from eqs. (5.23) and (5.24)

using

for the real dielectric constants.

[73.2.1.9] These predictions are obtained

from eqs. (5.23) and (5.24)

using ![]() and eqs. (5.13b)

and (6.12) with

and eqs. (5.13b)

and (6.12) with

![]() ,

and the exponent

,

and the exponent ![]() from Table 1.

[73.2.1.10] Figure 4(b) shows that these values

are indeed approached at low frequencies.

[73.2.1.11] Similarly, scaling theory predicts the exponent

from Table 1.

[73.2.1.10] Figure 4(b) shows that these values

are indeed approached at low frequencies.

[73.2.1.11] Similarly, scaling theory predicts the exponent ![]() for

for ![]() and

and ![]() corresponding

to distributions

corresponding

to distributions ![]() ,

, ![]() and

and ![]() in figure 5.

[73.2.1.12] Again, these values are approached

as seen fom figure 5(b),

although the power-law behavior

occurs over a limited frequency range

because

in figure 5.

[73.2.1.12] Again, these values are approached

as seen fom figure 5(b),

although the power-law behavior

occurs over a limited frequency range

because ![]() is not sufficiently

close to the critical region.

[73.2.1.13] Note that curve 8 in figure 5

has dropped below the percolation threshold,

and thus the conductivity increases as

is not sufficiently

close to the critical region.

[73.2.1.13] Note that curve 8 in figure 5

has dropped below the percolation threshold,

and thus the conductivity increases as ![]() for small

for small ![]() .

.

| Curve No. 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

|

|

0.798 | 0.053 | 3.716 | 1.863 | 3.147 | 9.261 | 28.793 | 20.484 |

|

|

0.298 | 0.035 | 1.067 | 0.619 | 0.889 | 1.545 | 2.400 | 2.029 |

|

|

19.197 | 13.819 | 21.956 | 25.162 | 34.950 | 96.046 | 186.010 | 115.270 |

|

|

1.585 | 1.370 | 1.664 | 1.674 | 1.741 | 1.648 | 1.751 | 1.489 |

|

|

5.996 | 3.835 | 16.616 | 9.639 | 14.204 | 52.196 | 259.700 | 3932.522 |

|

|

1.105 | 0.801 | 1.974 | 1.455 | 1.708 | 2.176 | 2.877 | 2.283 |

|

|

2.119 | 0.053 | 371.525 | 5.498 | 11.430 | 291.481 | 277.396 | 37.691 |

|

|

0.595 | 0.035 | 3.025 | 1.137 | 1.604 | 2.565 | 3.043 | 2.436 |

[73.2.2.1] The complexity and variability of ![]() obtained from the simple mean-field solutions

of this section correspond to the complexity

and variability of possible pore-space geometries.

[73.2.2.2] More approximate analytical investigations

of the solutions to eq. (3.2)

are necessary to identify simple parameters

characterizing

obtained from the simple mean-field solutions

of this section correspond to the complexity

and variability of possible pore-space geometries.

[73.2.2.2] More approximate analytical investigations

of the solutions to eq. (3.2)

are necessary to identify simple parameters

characterizing ![]() and

and ![]() which allow a better classification

of the solutions and thereby the possible geometries.

which allow a better classification

of the solutions and thereby the possible geometries.

| Curve No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| CPM | 0.6542 | 0.6940 | 0.5420 | 0.5858 | 0.5341 | 0.4059 | 0.3643 | 0.3334 |

| GCM | 0.7500 | 1.0000 | 0.3399 | 0.6048 | 0.4962 | 0.3415 | 0.3376 | 0.2841 |

F Sedimentary rock

[73.2.3.1] The present paper deals only

with simple homogeneous and isotropic porous media.

[73.2.3.2] Real rocks are highly inhomogeneous,

but they can also be discussed

within the present framework.

[page 74, §0]

[74.1.0.1] Sedimentary rocks exhibit two main types of porosity.

[74.1.0.2] Primary interparticle porosity

is the porosity between the grains

of the original sediment.

[74.1.0.3] Often, this pore space is changed

during diagenesis of the sediment.

[74.1.0.4] In particular cements between the grains

can exhibit a qualitatively different secondary porosity.[33]

[74.1.0.5] This situation can be treated within

the present formalism

by replacing the dielectric constant ![]() of the pore-filling fluid

with the effective dielectric constant

of the pore-filling cement.

[74.1.0.6] Naturally, the results must be much more complex,

as they contain additional

independent geometrical information describing the cement.

of the pore-filling fluid

with the effective dielectric constant

of the pore-filling cement.

[74.1.0.6] Naturally, the results must be much more complex,

as they contain additional

independent geometrical information describing the cement.